How does it manage this? Through sophisticated features that not only save the user a lot of time and money, but also incorporate the concept of sustainability. The new InsertBox Connect is therefore a small yet powerful solution that effortlessly keeps its contents safely under control.

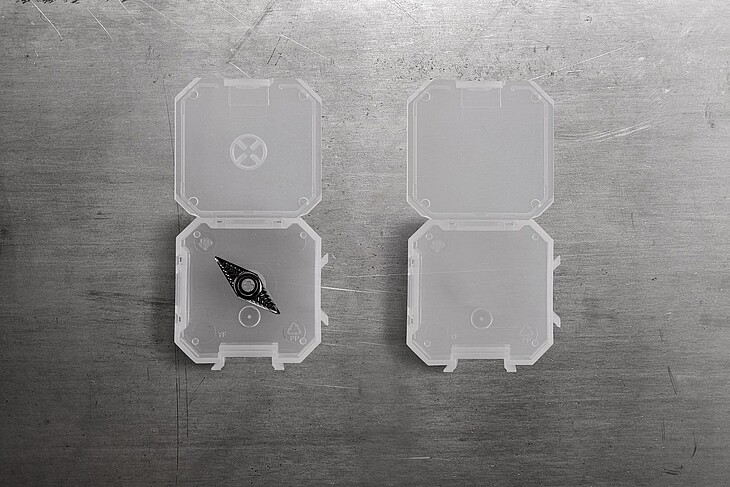

With only two sizes and various mounting geometries, the InsertBox Connect is the ideal individual packaging for a wide range of standardized indexable inserts with bores. Customized inserts are also possible. But there is even more to it – the new box is also available without a centering insert and can therefore be used in a number of different ways.

Makes foam materials superfluous

To protect sensitive cutting inserts, good cushioning is the top priority when it comes to the packaging. Typically, indexable inserts are carefully enclosed between soft foam materials and lie securely inside the packaging. The new InsertBox Connect takes a different approach. It dispenses with foam inserts, thus eliminating the need for this “sandwich system”. This is possible because the centering insert and spacer rings in the base and lid of the box prevent the blades from coming into contact with the surrounding plastic. Inside the closed box, the retaining pin is stabilized by means of an additional attachment point in the lid and thus remains intact even in the event of heavy impacts.

By eliminating the need for additional foam materials, the InsertBox Connect also contributes to sustainability, as single materials are much easier to recycle. By the way – our new packaging is also available in post-consumer recyclate.

The box that makes connections

The new packaging also impresses thanks to its practical plug-in function, which inspired the “Connect” part of its name. The individual boxes can be interconnected on all sides and can thus be combined in any size. Interconnected boxes form a smooth surface for labels, inscriptions, or tags. The new InsertBox Connect can also be stacked vertically, thanks to additional latching lugs that help to stabilize the boxes.

Summary: Our new InsertBox Connect allows a wide range of insert sizes to be covered with just one type of packaging. Foam materials are dispensed with completely, reducing both the number of packaging materials and the effort required to process orders – and saving storage space to boot. And by the way, the clever plug-in function enables numerous possible variations. The InsertBox Connect offers all of this and is therefore a true all-rounder.